In-Situ Chemical Oxidation & Soil Vapor Extraction Remediation Program

In-Situ Chemical Oxidation Remediation Program Implemented Concurrently with Soil Vapor Extraction for the Remediation of […]

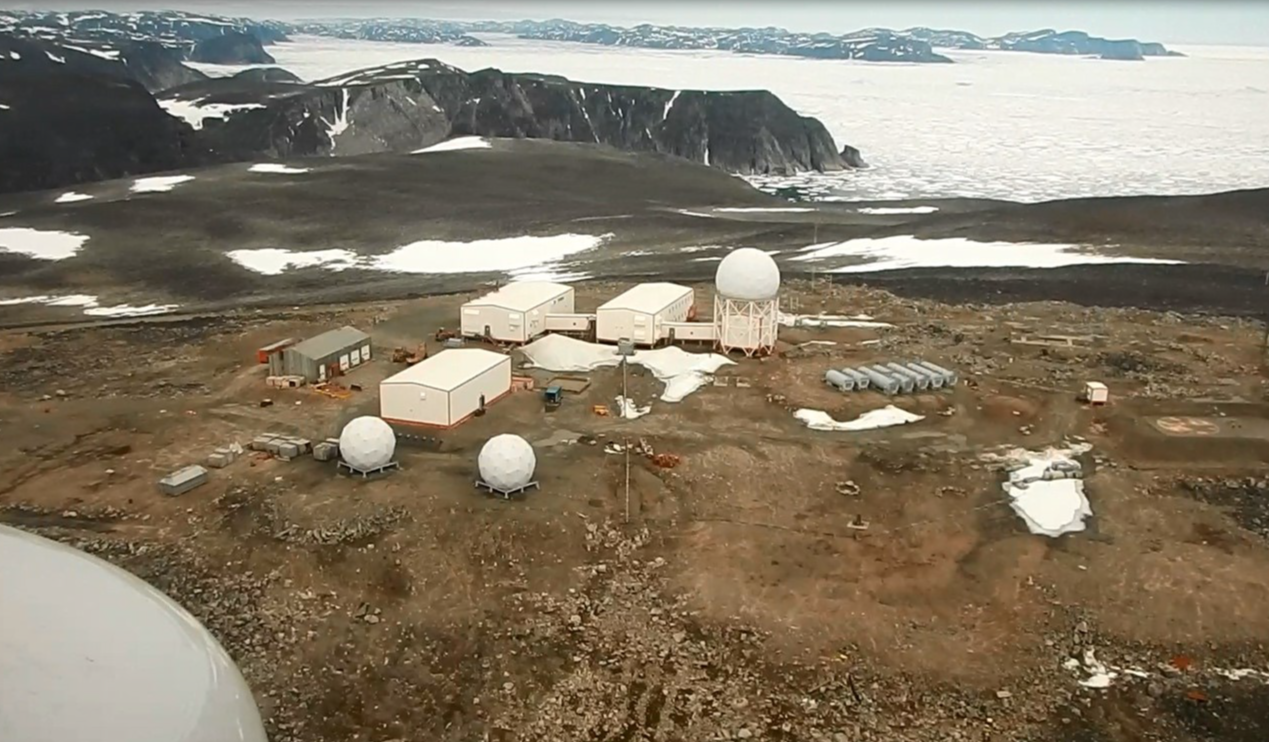

Weaver Consultants Group (WCG) provided emergency response actions, wastewater treatment system design, construction, installation, testing, optimization and operation, maintenance, and monitoring (OMM) services in response to an estimated 10,000+ gallon JetA1 release at a North Warning System radar station in the Arctic. The work scope included the expedited characterization, design, logistics coordination, foreign transportation, construction, and OMM of a wastewater (melted snow and water) treatment system to treat non-aqueous phase liquids (NAPL) and wastewater impacted with high concentrations of total suspended solids, phenol and Jet A1 hydrocarbons collected from the release area. The design effort included: expedited characterization of the wastewater; working in our remediation treatability laboratory to confirm the design basis to ensure a treatment in compliance with the surface water discharge requirements; working closely with and in the Process Technology Support (PTS) shop to design, fabricate and ship a control panel and programmable logic control system (PLC) incorporating the necessary monitoring programs, fail-safe alarms, and shut-down processes to enable 24/7 remote operation.

The design effort also included working with Geotech Environmental to design and construct an air stripper that could be disassembled and transported on a helicopter, working with a boiler company to re-engineer three small boilers to heat the wastewater to 120°F to attain the surface water discharge requirements for phenol and coordination with an Arctic sealift company to secure two 20-foot shipping containers to enclose and protect the wastewater treatment system piping and equipment from the harsh Arctic environment and sub-zero temperatures.

WCG successfully completed the design, procurement, construction, and start-up of the wastewater treatment system on an uninhabited, remote island in the Arctic in 90 days. The wastewater treatment system includes influent surge tanks, level, flow and temperature control, continuous monitoring equipment, a PLC, an oil water separator, an LNAPL recovery system contained in a separate Class 1 Division II shipping container, multiple bag filtration units, redundant influent boilers, an air stripper, parallel activated carbon vessels, and an ultraviolet oxidation polish system.

WCG’s OMM of this wastewater treatment system has resulted in the recovery of approximately 3,000 gallons of NAPL and the treatment and discharge of over 500,000 gallons of impacted wastewater in compliance with stringent Arctic surface water discharge standards.